Analog inputs can be mV, Volts, mili-Amps, Amps, AC, DC, or complex wave forms. Typical process controls applications take these measurements from sensors and transducers and convert them to 4 - 20 mA signal. There is still a huge infrastructure in most industries that support this. The 4 mA level represents a 0% measurement value, the 20 mA level represents the 100% measurement value. This provides an opportunity to signal a fault condition either intentionally by the transmitter or a unintentionally by a cut cable for example.

This design is based on the MCP3208 8 channel 12 Bit Analog to Digital converter form Microchip.

PCB Assembly complete with PIC Processor Module:

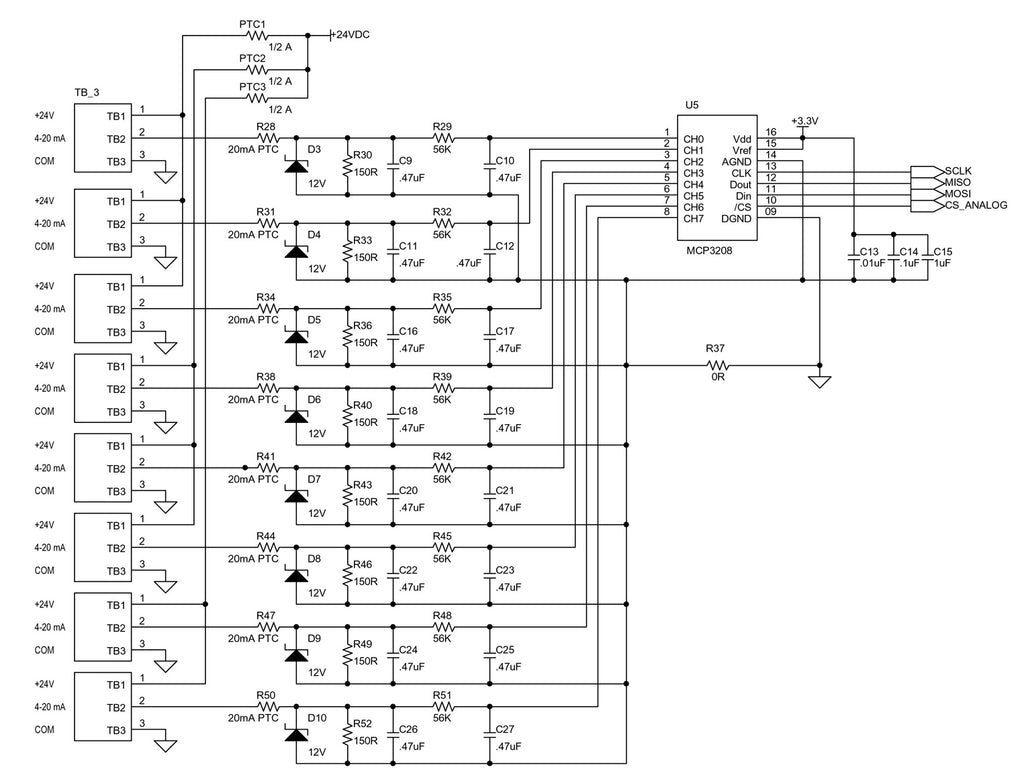

Schematic:

Each analog input 0 to 20 mA signal is convert to a voltage across the 150 Ohm Load Resistor giving a 0 to 3.0 V input to the MCP3208.

PCB Assembly with PIC Processor PCB detached:

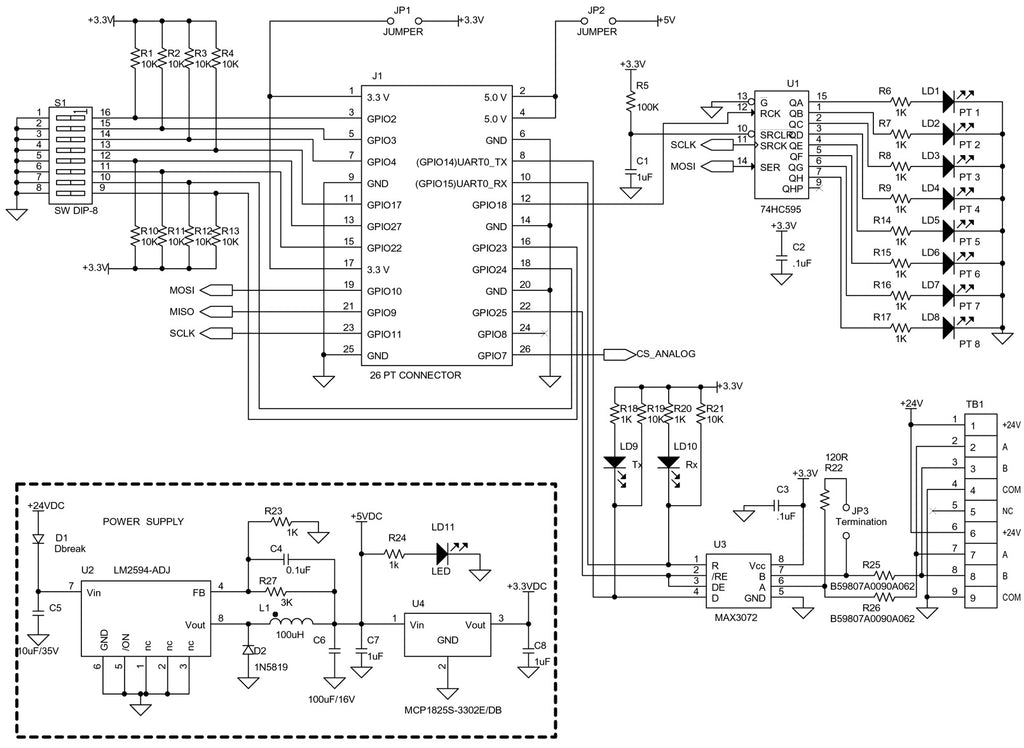

Some of the design criteria was to have the module be compatible with the Raspberry Pi, have RS485 I/O, have MODBUS RTU communication and have protection for the input circuits.

Here is the full specification:

Specifications:

- Power: 24 VDC

- RS485 Jumper Selectable 9600 or 19.2K Baud, N81

- Modbus RTU Protocol

- Modbus ID: Dipswitch Selectable

- Analog Inputs: 4-20 mA into 150 Ohm load, PTC Fuse Protection

- Resolution: 12 Bit ADC

- Calibration: Simple calibration via jumpers

Processor:

- PIC18F45K20, c/w ICSP Port

Indicators:

- Power On: BLUE LED

- Analog Input: 1 thru 8: GREEN LED ON when input above 2mA

- Heart Beat: AMBER LED (Flashes to indicate proper operation)

- RS485: GREEN LED Rx, RED LED Tx.

Options:

- DIN Rail Enclosure Bud Industries Model: DMB-4774

Schematic Page 2:

By removing the PIC PCB, the device now becomes Raspberry Pi Compatible:

For information regarding the PIC module, please see the post for the VP-EC-8KO.

Sample Source Code

This sample code uses the wiringPi library and the Geany C compiler. The code has been tested for:

- Reading the Dipswitch

- Reading the 8 channels of AD Counts from the MCP3208 AD Converter

- 20 mA into a 150 Ohm load resistor = 3.0 VDC

- MCP3208 uses the 3.3 VDC as a reference, therefore 20 mA = 3/3.3 * 4096 = 3723 AD Counts

- A1 thru A8 LED driver using the 74HC595 Serial Shift Register

/*

* main.c

*

* Copyright 2016 <pi@raspberrypi>

*

* This program is free software; you can redistribute it and/or modify

* it under the terms of the GNU General Public License as published by

* the Free Software Foundation; either version 2 of the License, or

* (at your option) any later version.

*

* This program is distributed in the hope that it will be useful,

* but WITHOUT ANY WARRANTY; without even the implied warranty of

* MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

* GNU General Public License for more details.

*

* You should have received a copy of the GNU General Public License

* along with this program; if not, write to the Free Software

* Foundation, Inc., 51 Franklin Street, Fifth Floor, Boston,

* MA 02110-1301, USA.

*

*

*/

#include <stdio.h>

#include <string.h>

#include <errno.h>

#include <stdlib.h>

#include <wiringPi.h>

#include <wiringPiSPI.h>

// Define Pins RPi V2 Series B

#define PIN_SW1 2

#define PIN_SW2 3

#define PIN_SW3 4

#define PIN_SW4 17

#define PIN_SW5 27

#define PIN_SW6 22

#define PIN_SW7 24

#define PIN_SW8 23

#define PIN_08 14 // Used for testing UART Leds Tx and Rx

#define PIN_10 15

#define PIN_EN_LED 18 // CS for LEDS (74HC595)

#define PIN_EN_AD 7 // CS for Analog Inputs MCP3208

#define mA_20 3723 // 20 mA * 150Ohms = 3 Vdc/3.3 Vdc full scale * 4096 Counts

#define mA_Fault 372 // 2 mA Fault level in AD Counts

// Function Prototypes

void Initialize_Pi_Hardware(void);

int Read_Switch(void);

void Update_Leds(void);

unsigned int Update_Analog(unsigned char channel);

// Variables

unsigned int AN_AD[8];

int Switch;

int main(void) {

int i;

wiringPiSetupGpio(); // Initialize the wiringPi GPIO

Initialize_Pi_Hardware(); // Set the GPIO Bit directions

digitalWrite(PIN_EN_LED, HIGH); // Set the EN LED CS HIGH

digitalWrite(PIN_EN_AD, HIGH); // Set the EN AD CS HIGH

while(1)

{

Switch = Read_Switch(); // Read the 8 Point Dip Switch

AN_AD[0] = Update_Analog(0); // Read Channel A0 AD Counts from MCP3208

AN_AD[1] = Update_Analog(1); // Read Channel A1 AD Counts

AN_AD[2] = Update_Analog(2); // Read Channel A2 AD Counts

AN_AD[3] = Update_Analog(3); // Read Channel A3 AD Counts

AN_AD[4] = Update_Analog(4); // Read Channel A4 AD Counts

AN_AD[5] = Update_Analog(5); // Read Channel A5 AD Counts

AN_AD[6] = Update_Analog(6); // Read Channel A6 AD Counts

AN_AD[7] = Update_Analog(7); // Read Channel A7 AD Counts

printf("ID = %d \n", Switch); // Print the Data

for(i = 0; i < 8; i++) {

printf("Channel AN%d = %d ADC, %0.2f mA \n", (i+1), AN_AD[i], (float)AN_AD[i] * 20 / mA_20);

}

printf("\n");

Update_Leds(); // Update AN1 thru A8 LEDs using the 74HC595

delay(1000); // Delay 1 Second loop

}

return 0;

}

// Update Analog Inputs using the MCP3208

unsigned int Update_Analog(unsigned char channel) {

unsigned int adc, input;

unsigned char buf[3];

wiringPiSPISetup(1, 100000);

input = 0x0600 | (channel << 6);

buf[0] = (input >> 8) & 0xff;

buf[1] = input & 0xff;

buf[2] = 0;

digitalWrite(PIN_EN_AD, LOW);

wiringPiSPIDataRW(1,buf,3);

adc = ((buf[1] & 0x0f ) << 8) | buf[2];

digitalWrite(PIN_EN_AD, HIGH);

return adc;

}

// Update the A1 thru A8 LEDs using the 74HC595

// If the AD Counts are > than the AD Fault Counts, the respective Ax LED turns on

void Update_Leds(void) {

unsigned char buf[2];

unsigned char value;

value = 0;

if(AN_AD[0] > mA_Fault) {

value |= 0x01;

}

if(AN_AD[1] > mA_Fault) {

value |= 0x02;

}

if(AN_AD[2] > mA_Fault) {

value |= 0x04;

}

if(AN_AD[3] > mA_Fault) {

value |= 0x08;

}

if(AN_AD[4] > mA_Fault) {

value |= 0x10;

}

if(AN_AD[5] > mA_Fault) {

value |= 0x20;

}

if(AN_AD[6] > mA_Fault) {

value |= 0x40;

}

if(AN_AD[7] > mA_Fault) {

value |= 0x80;

}

buf[0] = value;

wiringPiSPISetup(0, 100000);

wiringPiSPIDataRW(0,buf,1);

digitalWrite(PIN_EN_LED, LOW);

delay(1);

digitalWrite(PIN_EN_LED, HIGH);

}

// Read the Dipswitch as a value from 0 thru 255, to be used as the Modbus ID value

int Read_Switch(void) {

int value;

value = 0;

if(!digitalRead(PIN_SW1)) {

value |= 0x01;

}

if(!digitalRead(PIN_SW2)) {

value |= 0x02;

}

if(!digitalRead(PIN_SW3)) {

value |= 0x04;

}

if(!digitalRead(PIN_SW4)) {

value |= 0x08;

}

if(!digitalRead(PIN_SW5)) {

value |= 0x10;

}

if(!digitalRead(PIN_SW6)) {

value |= 0x20;

}

if(!digitalRead(PIN_SW7)) {

value |= 0x40;

}

if(!digitalRead(PIN_SW8)) {

value |= 0x80;

}

return value;

}

// Initialze the GPIO pin directions

void Initialize_Pi_Hardware(void) {

pinMode(PIN_08, OUTPUT);

pinMode(PIN_10, OUTPUT);

pinMode(PIN_EN_LED, OUTPUT);

pinMode(PIN_EN_AD, OUTPUT);

pinMode(PIN_SW1, INPUT);

pinMode(PIN_SW2, INPUT);

pinMode(PIN_SW3, INPUT);

pinMode(PIN_SW4, INPUT);

pinMode(PIN_SW5, INPUT);

pinMode(PIN_SW6, INPUT);

pinMode(PIN_SW7, INPUT);

pinMode(PIN_SW8, INPUT);

}